1, the use of eccentric shaft and lower excitation frequency of the five piston structure, with low noise characteristics;

2, start torque, low speed stability, and can run smoothly at very low speed;

3, the patented technology of the plane compensation with oil pan, good reliability, less leakage; piston and plunger sleeve seal ring seal, which has a high volume efficiency;

4, the crankshaft and the link between the roller support, which has a high mechanical efficiency;

5, the direction of rotation reversible, the output shaft to withstand a certain radial and axial external force;

6, with a high power quality ratio, the volume weight is relatively small.

Product application range

Products can be widely used in mining construction, engineering machinery, lifting transport equipment, heavy metallurgical machinery, oil and coal mining machinery, ship deck machinery, machine tools, plastic machinery, geological drilling equipment, and other mechanical hydraulic transmission system. Especially for the screw drive of the injection molding machine, to enhance the winch, the drive of the reel, a variety of rotary mechanism drive, track and wheel drive mechanism drive and other transmission machinery.

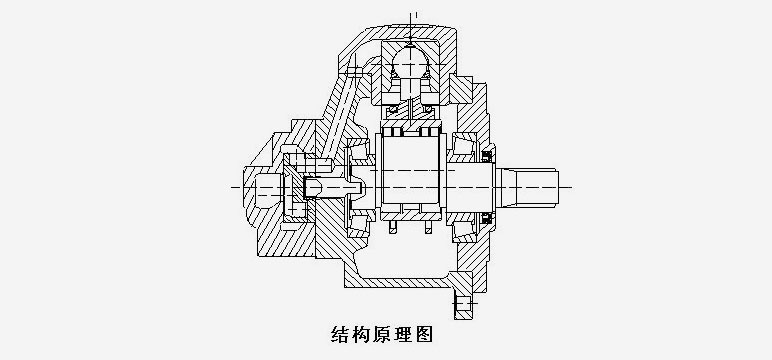

Structural principle

The plunger cylinder of the pressure oil is subjected to the hydraulic pressure to produce a thrust force P on the plunger body. The thrust through the connecting rod in the center of the crankshaft, so that the output shaft rotation, while the oil plate with the rotation, when the plunger body position to reach the bottom dead center, the plunger cylinder will be connected to the oil pan, The plunger is pushed up by the crankshaft. At this point, after the work of the hydraulic oil through the oil pan to return to the tank. Each plunger body connected to the high and low pressure oil, the pillar of the output shaft center of the drive torque generated by the same direction, so that the motor output shaft to obtain a continuous and smooth torque. When changing the direction of the oil flow, the direction of rotation of the motor can be changed. If the oil pan can be rotated 180 ° assembly can also achieve the motor reversal.

Several formulas used in the design

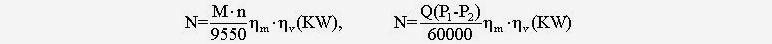

1, the actual output torque of the hydraulic motor: M = 0.159 (P1-P2) q • η m (N.m)

Where: P1, P2 --------- are the hydraulic motor inlet and outlet pressure (MPa)

Q -------------- Displacement of hydraulic motor (ml / r)

Ηm ------------ hydraulic motor mechanical efficiency

2 . Hydraulic motor output power

Where: n ----------------- Hydraulic motor speed (r / min)

Q ------------------ Enter the flow rate of the hydraulic motor (ml / min)

Ηv -------------- Hydraulic motor volumetric efficiency

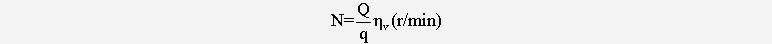

3. Hydraulic motor speed:

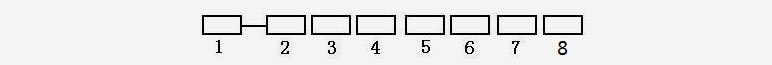

Model identification instructions

1, motor model / Model

2, series / series

3, nominal displacement / Displacement (ml / r)

4, the output shaft form / Output shaft

1). No letter indicates the standard rectangular spline shaft (centered with centering)

2) .B for the flat key; the footnote indicates the same size as the BM type cycloid hydraulic motor or other brand (with transition flange plate)

3) .D installation connection size and Kunshan Hydraulic Factory 1JMD with the same displacement hydraulic motor

4) .The internal spline (with inner diameter centering); footnote digital and Ningbo hydraulic motor factory production QJM series installation the same size (with transition flange plate)

5) .GM, SL said installation connection size and Italy SAI company production M series, L series, GM series hydraulic motor the same, footnote number that different types of installation size

5, oil pan and access port thread / Distributors an I / O port thread

Old factory address: NO.199 Dongming RD. Zhenhai Ningbo P.R.China

Old factory address: NO.199 Dongming RD. Zhenhai Ningbo P.R.China

Tel: +86-574-55335156 | +86-574-55336188

Tel: +86-574-55335156 | +86-574-55336188

Email: dandunhyd@163.com

Email: dandunhyd@163.com

Ms. Jenny Wong

Ms. Jenny Wong

Mobile / Whatsapp: +86-13777205416

Mobile / Whatsapp: +86-13777205416

Web:www.dandunhyd.com | www.nbdandun.com

Web:www.dandunhyd.com | www.nbdandun.com